Branding Solutions

There are a multitude of branding options and solutions available. The different options depend on the type of product you are looking to decorate, with some options being more cost-effective than others.

Colourflex Transfer

Colourflex® utilizes a CMYK+W digital print process for branding apparel and fabrics.

Advantages:

- Ideal for full-color complex images and approximate spot color branding.

- High-definition vibrant matte finish suitable for various garment fabrics.

- Eco-friendly water-based inks.

- Durable and flexible with a soft-touch matte finish machine washable.

- Efficient self-weeding technology.

- Single setup charge regardless of the number of print colors.

- Immediate shipping post-printing.

Limitations:

- Metallic and neon/fluorescent colors cannot be reproduced.

- Thin clear glue lines may be visible around image edges.

- Variable data printing is not available.

- Minimum detail advised at 1mm.

Artwork Requirements:

- Artwork can be vector or bitmap format.

- Bitmap images must be above 300DPI resolution at actual print size.

- Convert fonts to outlines/objects to avoid font conflicts.

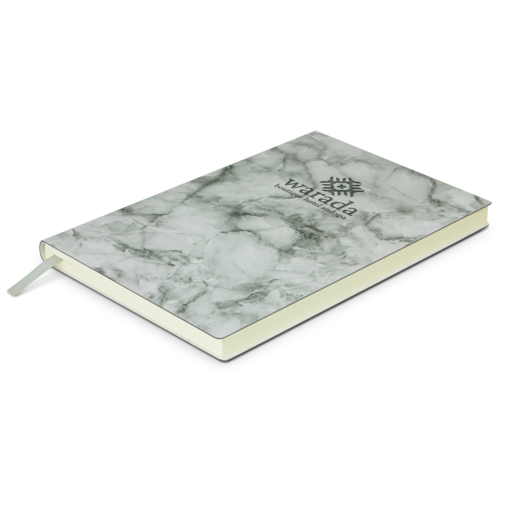

Debossing

Debossing (often referred to as ‘Blind’ debossing) involves pressing a heated custom metal plate onto the product to create an impression.

Advantages:

- High perceived value.

- Permanent branding as part of the product.

- Immediate shipping post-heat pressing.

- Two-tone finish possible on some products.

Limitations:

- Variable data printing is not possible.

Artwork Requirements:

- Artwork must be in vector format.

- Convert fonts to outlines/objects to avoid font conflicts.

Digital Label

Digital adhesive labels are used for products that cannot be branded using other methods, printed with a digital press and applied to the product.

Advantages:

- Excellent for vivid full-color images and closely matched spot color branding.

- Variable data printing including individual names.

- Single setup charge regardless of the number of print colors.

- Edge-to-edge branding achievable.

- Custom shape cutting available.

Limitations:

- Metallic and neon/fluorescent colors are unavailable.

- White print not possible on clear silver or gold stock.

Artwork Requirements:

- Artwork can be vector or bitmap format.

- Bitmap images must be above 300DPI resolution at actual print size.

- Add a 3mm bleed if artwork extends to the edge of the product.

Digital Packaging Print

Digital Packaging Print uses CMYK digital printing for paper bags and pre-cut flat-pack corrugated media.

Advantages:

- Ideal for full-color, complex images with gradients.

- Variable data printing on select products.

- Single setup charge, regardless of the number of print colors.

- Instant drying allows immediate shipping.

Limitations:

- Certain colors, including closely matched PMS, RGB, metallic, and neon colors, cannot be produced.

- Dark substrates cannot be printed as white ink is not used beneath the artwork.

- Edge-to-edge branding is not achievable.

Artwork Requirements:

- Artwork can be vector or bitmap format.

- Bitmap images must be above 300DPI resolution at actual print size.

- Convert fonts to outlines/objects to avoid font conflicts.

Digital Print

Digital Print is used for printing media such as paper, vinyl, and magnetic material.

Advantages:

- Ideal for full-color, complex images with gradients.

- Variable data printing available on select products.

- Single setup charge, regardless of the number of print colors.

- Immediate drying for quick shipping.

- Custom shape cutting available.

Limitations:

- Metallic and neon/fluorescent colors are unavailable.

- White print not possible on kraft, clear, silver, or gold stock.

- Dark substrates cannot be printed as white ink is not used beneath the artwork.

Artwork Requirements:

- Artwork should be in vector format or 300DPI bitmap.

- Bitmap images must be above 300DPI resolution at actual print size.

- Add a 3mm bleed if artwork extends to the edge of the product.

Direct Digital

Direct Digital Printing transfers ink directly from the print heads of an inkjet machine to the product, suitable for both full-color and spot color branding on flat or slightly curved surfaces.

Advantages:

- Ideal for dark-colored products as a layer of white ink can be used beneath the artwork.

- Variable data printing available on select products.

- Immediate drying for quick shipping.

- Larger print areas and close-to-edge printing possible.

- Single setup charge, regardless of the number of print colors.

Limitations:

- Some colors, including metallic and neon/fluorescent, cannot be reproduced.

- Branding area size is limited on curved surfaces.

- Larger print areas may be more expensive.

Artwork Requirements:

- Artwork can be vector or bitmap format.

- Bitmap images must be above 300DPI resolution at actual print size.

- Add a 3mm bleed if artwork extends to the edge of the product.

Embroidery

Embroidery offers high perceived value and depth for branding textile products using rayon thread stitched into the product.

Advantages:

- Single setup charge applies per position for up to 12 thread colors.

Limitations:

- Approximate PMS color matches; threads chosen from available colors.

- Variable data printing is not available.

- Metallic embroidery colors may incur special pricing.

Artwork Requirements:

- Vector artwork preferred.

- Convert fonts to outlines/objects to avoid font conflicts.

- Avoid fine detail; minimum text heights:

Imitation Etch

Imitation Etch uses a special pad printing ink to produce an etch-like effect on glass products.

Advantages:

- More affordable than real etching.

- Suitable for curved or uneven products.

- Subtle finish with a higher perceived value resembling etching.

Limitations:

- Halftones are inconsistently reproduced.

- Branding area size is limited on curved surfaces.

- Curing period required before shipping.

- Variable data printing is not available.

Artwork Requirements:

- Artwork must be in vector format.

- Convert fonts to outlines/objects to avoid font conflicts.

Laser Engraving

Laser Engraving permanently engraves artwork into the surface of the product using a laser, suitable for various materials.

Advantages:

- High perceived value.

- Permanent branding as part of the surface.

- Large branding areas available on curved products.

- Variable data printing available on select products.

- Immediate shipping after engraving.

Limitations:

- Fine detail may be lost on smaller products like pens.

Artwork Requirements:

- Artwork must be in editable vector format.

- Convert fonts to outlines/objects to avoid font conflicts.

Pad Print

Pad Printing uses a silicone pad to transfer images from a laser-etched printing plate to a product, effective for uneven or curved surfaces.

Advantages:

- Ideal for curved or uneven products.

- Sharp, clean images with detail as fine as 0.4mm, minimum text size is 5pt.

- Close PMS matches possible on white or light-colored products.

- Metallic gold and silver ink available.

- White under base available for darker products.

- Multi-color registration available

Limitations:

- Halftones are inconsistently reproduced.

- Variable data printing is not available.

- Close PMS matches on darker products are approximate; white base improves print.

- Curing period required for some inks.

- Each color requires its own setup charge.

- Neon/fluorescent colors are unavailable.

Artwork Requirements:

- Artwork should be in vector format.

- Convert fonts to outlines/objects to avoid font conflicts.

Resin Coated Finish

Resin Coated Finish involves printing artwork onto a vinyl material with adhesive and coating it with crystal-clear resin, creating a permanent decal.

Advantages:

- Ideal for vivid full-color images and closely matched spot color branding.

- Produces a 3D effect that elevates perceived value.

- Variable data printing available on select products.

- Edge-to-edge branding achievable.

- Single setup charge, regardless of the number of print colors.

Limitations:

- Larger print areas can be more expensive.

- White, metallic gold, silver, and neon colors are unavailable.

- Resin requires curing for one day before shipping.

Artwork Requirements:

- Artwork can be vector or bitmap format.

- Bitmap images must be above 300DPI resolution at actual print size.

Rotary Digital Print

Rotary Digital Print involves UV ink and varnish coating for detailed gloss artwork on cylindrical products.

Advantages:

- Ideal for large or complex full-color gloss prints.

- Instant drying allows for immediate shipping.

- Single setup charge, regardless of the number of print colors.

- No loss of print vibrancy on darker products.

Limitations:

- Production speed may result in longer lead times.

- Some colors, including metallic and neon/fluorescent, cannot be reproduced.

- Small gap between start and end of the print as it does not wrap completely around the product.

- More expensive compared to other branding options.

Artwork Requirements:

- Artwork can be vector or bitmap format.

- Bitmap images must be above 300DPI resolution at actual print size.

- Convert fonts to outlines/objects to avoid font conflicts.

Rotary Screen Print

Rotary Screen Printing uses a fine mesh screen to print cylindrical products.

Advantages:

- Large print areas possible on cylindrical products.

- Close PMS matches available on white or light-colored products.

- Quick-drying inks allow immediate shipping.

- Metallic gold and silver colors available.

- Multi-color registration up to five colors.

Limitations:

- Close PMS matches on darker products are approximate; a white base improves print.

- Variable data printing is not available.

- Each color requires its own setup charge.

Artwork Requirements:

- Artwork must be in vector format.

- Convert fonts to outlines/objects to avoid font conflicts.

Screen Print

Screen Printing uses a fine mesh screen to print flat objects.

Advantages:

- Large print areas possible on flat products.

- Close PMS matches available on white or light-colored products.

- Quick-drying inks allow immediate shipping.

- Fluorescent, metallic gold, and silver inks available on select textile products.

- Multi-color registration available, up to five colors.

Limitations:

- Close PMS matches on darker products are approximate; a white base improves print.

- Variable data printing is not available.

- Each color requires its own setup charge.

Artwork Requirements:

- Artwork must be in vector format.

- Convert fonts to outlines/objects to avoid font conflicts.

Silicone Digital Print

Silicone Digital Print is a CMYK+W digital process designed for silicone surfaces.

Advantages:

- Crisp, clear, high-definition artwork.

- Durable, flexible branding suitable for hand washing.

- Ideal for dark-colored products with a white ink base.

- Full-color images and approximate spot color branding.

- Matte finish that does not crack or fade.

Limitations:

- Some colors, including metallic and neon/fluorescent, cannot be reproduced.

- Variable data printing is not available.

- Minimum detail advised at 0.7mm.

Artwork Requirements:

- Artwork can be vector or bitmap format.

- Bitmap images must be above 300DPI resolution at actual print size.

- Convert fonts to outlines/objects to avoid font conflicts.

Sublimation Print

Dye Sublimation Print is used for products with a special coating or suitable fabrics. It involves printing sublimation ink onto transfer paper and then heat pressing it onto the product.

Advantages:

- Sublimation ink embeds into the product, preventing ink build-up.

- Ideal for vivid full-color images and closely matched spot color branding.

- Variable data printing available on select products.

- Edge-to-edge branding achievable on some products.

- Single setup charge, regardless of the number of print colors.

Limitations:

- Only suitable for products with white surfaces.

- Metallic, neon/fluorescent colors, and white ink are not available.

- Fine detail/text may have minor color bleed.

Artwork Requirements:

- Artwork can be vector or bitmap format.

- Bitmap images must be above 300DPI resolution at actual print size.

- Add a 3mm bleed if artwork extends to the edge of the product.

![]()